ANN ARBOR – A breakthrough in solar manufacturing developed in Australia could have far-reaching implications for Michigan’s clean-energy transition — particularly as the state grapples with rising electricity demand from data centers, electric vehicle production, and advanced manufacturing.

Researchers at UNSW Sydney have developed a contactless solar cell inspection technology that could make solar energy cheaper, more reliable, and easier to produce. The innovation has the potential to save the global solar industry more than $1 billion a year by speeding up manufacturing, reducing waste, and improving panel quality.

Unlike conventional inspection systems that physically touch fragile solar cells, the UNSW method never makes contact. That allows manufacturers to detect defects earlier, reduce breakage, and keep production lines moving faster. The result is higher yields, fewer delays, and lower costs — benefits that ripple through the entire clean-energy supply chain.

The technology is now moving toward commercial deployment after years of development. The project received a AU$400,000 TRaCE Lab to Market Fund grant, along with AU$1 million in investment from UNSW spin-off BT Imaging. Together, the partners aim to establish the system as a global testing standard for both today’s silicon solar cells and next-generation designs.

“Our goal is to deliver inspection tools that are more efficient and reliable,” said Ziv Hameiri, a professor at UNSW involved in the project. “That gives manufacturers deeper insight into their processes while driving down costs.”

Why Michigan Stands to Benefit

While the technology was developed overseas, its impact could be felt directly in Michigan, where solar power is becoming a cornerstone of long-term energy planning.

Michigan currently has roughly 2 gigawatts of installed solar capacity, with thousands of additional megawatts planned over the coming decades. Utilities are scaling up renewable generation as electricity demand rises and carbon-reduction goals tighten.

Consumers Energy has committed to deploying 8,000 megawatts of solar by 2040, while DTE Energy has set a goal of achieving net-zero carbon emissions by 2050, with large-scale solar playing a central role in its generation mix.

Lower-cost, higher-quality solar panels enabled by advanced inspection technologies could help utilities deploy projects faster and more efficiently — easing pressure on the grid while keeping long-term costs in check for customers.

Data Centers Raise the Stakes

The timing is critical. Michigan is seeing a surge in proposed data center projects tied to artificial intelligence, cloud computing, and enterprise digital infrastructure. These facilities consume enormous amounts of electricity and require highly reliable power, accelerating demand growth across utility service territories.

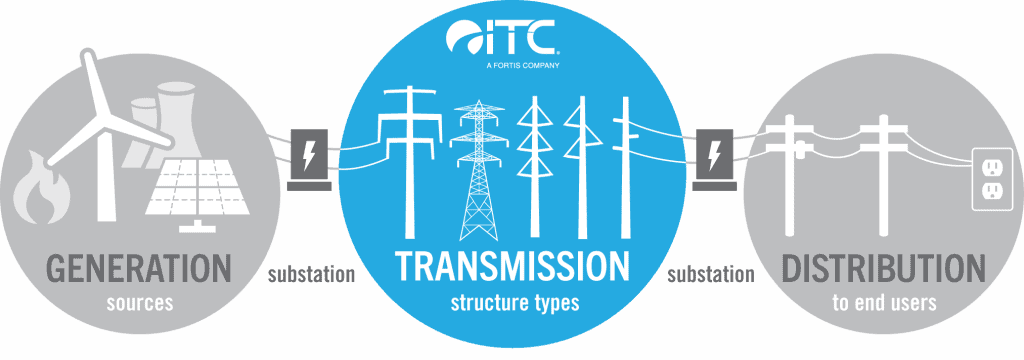

Utilities have warned that data centers can force rapid investment in new generation, transmission, and distribution infrastructure — costs that ultimately flow through to ratepayers. Cheaper and more dependable solar power could help offset that demand, particularly when paired with battery storage or deployed directly at data center campuses.

For manufacturers and data center operators, improved solar reliability reduces operational risk and supports sustainability commitments increasingly demanded by customers and investors. For communities, expanding clean energy helps limit pollution and supports healthier air quality as industrial activity grows.

As Michigan works to balance economic development, grid reliability, and energy affordability, innovations that reduce the cost and complexity of solar manufacturing could play a quiet but crucial role — even when those breakthroughs originate half a world away.