In the oil and gas industry, issues like energy waste, environmental impact, operational inefficiencies, and safety concerns have long been at the forefront of industry discussions. However, the emergence of the Internet of Things (IoT) provides hope, as it offers innovative solutions to tackle these challenges head-on. IoT technology presents a promising avenue to not only improve the efficiency and safety of oil and gas operations but also to reduce their environmental footprint significantly.

Most oil and gas companies (more than 75%) intend to increase their utilization of IoT solutions in the current year to gain a deeper understanding of their sustainability efforts. Besides, over 80% of these companies consider IoT tools crucial for improving their efforts to reduce their carbon footprint, which measures their environmental impact regarding greenhouse gas emissions and other environmental factors. These statistics clearly show us that there is a strong and growing interest in using IoT technology to support sustainability and environmental goals within the oil and gas industry.

Here you can find more about IoT in Transportation.

Thus, in this article, we’ll explore how IoT is poised to revolutionize the industry, addressing these pressing concerns while fostering a more sustainable future. Stay tuned and keep reading.

What are IoT appliances?

In our contemporary world, the demand for sustainable solutions has never been more acute, and IoT stands as a powerful instrument for addressing this need. IoT technology finds application across a diverse spectrum of industries, such as manufacturing, agriculture, healthcare, transportation, and oil and gas.

In the oil and gas industry specifically, IoT refers to using interconnected sensors, devices, and equipment to collect and transmit real-time data from operations such as drilling, production, and distribution. This data helps improve efficiency and safety by allowing remote monitoring, predictive maintenance, and better decision-making, which, in turn, significantly influences sustainability.

Considering that in 2022, the global market for the IoT in the oil and gas industry had a total value of USD 11.2 billion, the IoT market in the oil and gas industry is expected to grow, as it is further projected to experience a compound annual growth rate (CAGR) of 9.7% from the year 2023 to 2032.

IoT impact on sustainability in the gas and oil industry

The gas and oil industry is actively looking for ways to be greener. IoT definitely has the power to transform the gas and oil industry by making it more sustainable and eco-friendly. Let’s explore how IoT is making a difference in this sector:

Real-time, remote monitoring

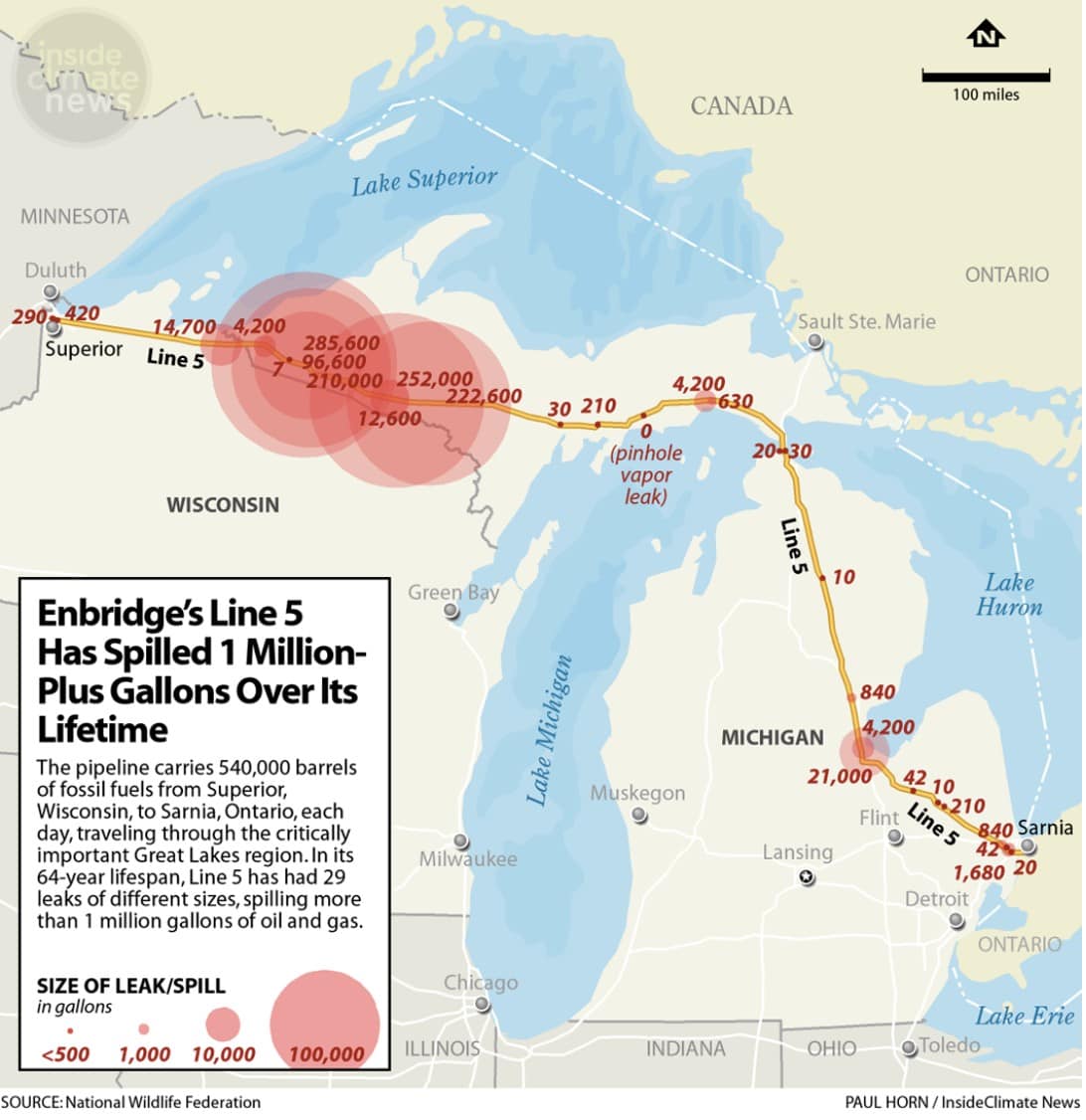

IoT devices, like sensors and drones, monitor various aspects of oil and gas operations. This real-time data helps identify and address issues promptly, reducing the risk of leaks, spills, and other environmental incidents, especially in situations like underwater gas leak detection.

For instance, Shell, a global energy giant, has adopted IoT technology to monitor its oil and gas facilities. Through IoT sensors and devices, Shell improves operational efficiency, ensures environmental safety, and advances sustainability in the industry.

Data analytics

IoT solutions in the oil and gas sector collect a wealth of data from various sources, including sensors on drilling equipment, pipelines, and production facilities. This data includes information on temperature, pressure, flow rates, equipment performance, and environmental conditions. IoT-generated data allows for more efficient drilling techniques, predicting and preventing equipment failures, optimizing equipment performance, and reducing energy consumption and operational costs, ultimately leading to greater environmental sustainability and improved overall efficiency.

For instance, Chevron, one of the world’s major energy companies, has entered into a 7-year partnership with Microsoft to adopt IoT technologies, which will assist Chevron in leveraging real-time data and advanced analytics for optimizing its operations, including exploration, reservoir management, production, logistics, and marketing efforts.

Energy efficiency

IoT enhances energy efficiency in the gas and oil industry by allowing real-time monitoring and control of lighting, heating, and cooling systems, adjusting them based on occupancy and operational needs, thus reducing energy waste. Predictive maintenance for HVAC systems ensures they operate efficiently, preventing energy loss due to equipment malfunctions.

Continuous energy monitoring and analytics help identify opportunities for improvement, and IoT technology optimizes the gas-to-liquid conversion process, reducing gas flaring and associated greenhouse gas emissions. Besides, it streamlines supply chain logistics, minimizing energy consumption in transportation and storage, and improves the precision and responsiveness of environmental controls.

Predictive maintenance

Let’s look at the case of British Petroleum (BP), one of the world’s largest energy companies. BP has harnessed IoT and machine learning to revolutionize its fuel stations. In Germany, BP introduced crewless diesel stations equipped with IoT sensors that continuously monitor environmental variables and equipment conditions, sending data to the cloud. This proactive approach allows early detection of issues, preventing disruptions and reducing maintenance costs.

You can imagine this technology reducing the cost of compressor repairs. At the moment, replacing these pieces of equipment is expensive and many fail randomly, leading to downtime at businesses and most costly maintenance and insurance premiums. Sensors, though, combined with ML could prevent this and give industry the jump on failures, allowing for scheduled maintenance instead of forced cessation of operations.

Meanwhile, in Mexico, BP introduced “Talk2Me,” an AI-powered support system that uses natural language processing and Alexa to provide instant answers to technicians’ common questions. This innovative approach has reduced help desk calls by 40%, improving efficiency, enhancing the customer experience, and marking the start of a broader company-wide exploration of IoT and machine learning to modernize operations and improve customer satisfaction.

Safety

All advantages that were mentioned above, such as real-time monitoring, predictive maintenance of equipment, early detection of safety-critical events, and immediate alerts to response teams, significantly improve safety in the gas and oil industry by reducing the risk of accidents and hazardous incidents. It allows remote monitoring, minimizing human exposure to high-risk areas, and ensures compliance with safety and environmental standards. Wearable IoT devices also improve personnel safety by detecting abnormal conditions and providing timely alerts.

Challenges and barriers

High implementation costs

High initial implementation costs can be a significant barrier to adopting IoT solutions. Deploying IoT infrastructure, sensors, and devices often entails substantial upfront investments in hardware, software, and the necessary skilled workforce. These initial costs can strain a company’s budget and financial resources. Nevertheless, it’s crucial to recognize that, over time, the efficiency gains, cost savings, and operational improvements facilitated by IoT often far outweigh the initial expenses, contributing to sustainable and long-term success in the industry.

Data security and privacy issues

One more barrier that arises is security concerns. Did you know that 98% of all IoT device communication occurs without encryption, leaving personal and sensitive data vulnerable on the network? This alarming statistic highlights the significant data security and privacy concerns surrounding the IoT. Without proper encryption measures, attackers can eavesdrop on unencrypted network traffic, intercepting personal or confidential information.

Future trends

The rapid evolution of IoT technologies heavily influences future trends in the oil and gas industry. Some key upcoming trends include:

- the adoption of edge computing for real-time data analysis;

- the rollout of 5G connectivity for improved remote monitoring;

- predictive maintenance using IoT sensors and analytics;

- increased focus on environmental monitoring and compliance;

- improvement of cybersecurity solutions to protect against cyber threats and a drive for greater energy efficiency in operations.

One noteworthy development is the concept of “Digital Twins,” where virtual replicas of physical assets or processes are created using real-time IoT data to improve decision-making and optimize performance.

These trends definitely represent the industry’s ongoing efforts to enhance sustainability, safety, and operational efficiency.

About Author

Kseniia Vyshyvaniuk is a highly experienced content manager and tech writer at KITRUM, a software development company. With over 5 years of experience in the industry, she is a true tech geek and stays up-to-date w